Quality Control at ZONG Cable

Building a competitive advantage through quality management.

Our Quality Commitment: Engineered for Reliability, Verified by Precision

At ZONG Cable, quality is not an afterthought—it is the fundamental principle woven into every stage of our process. From initial design to final shipment, we implement a rigorous, multi-layered quality management system to ensure that every cable delivers consistent, high-performance, and reliable connectivity.

Beauty starts with the details

The defect detection for the entire cable can examine the surface quality of the wire, the quality of the copper core, and provide a detailed report on all possible defects, including pictures of the defects and their standard names. Do you want to know what specific elements are detected by the zong cable? Please refer to our main checklist for surface defects.

Copper raw material

Twisted process

Braiding Process

Connector Welding

Injection Molding

Finished product testing

Our End-to-End Quality Control System

1. Design & Development Phase

Quality begins with superior design. Our engineers focus on:

Robust Design: Utilizing premium materials and optimal construction for durability and performance.

Specification Compliance: Designing all products to meet or exceed international standards (HDMI, DisplayPort, TIA/EIA, ISO/IEC).

Prototype Validation: Thoroughly testing prototypes against target specifications before mass production.

2. Incoming Material Control

We ensure integrity from the very source.

Vetted Suppliers: Partnering with certified suppliers of copper, shielding, and connectors.

Material Inspection: Conducting sampling tests on raw materials for conductivity, durability, and dimensional accuracy.

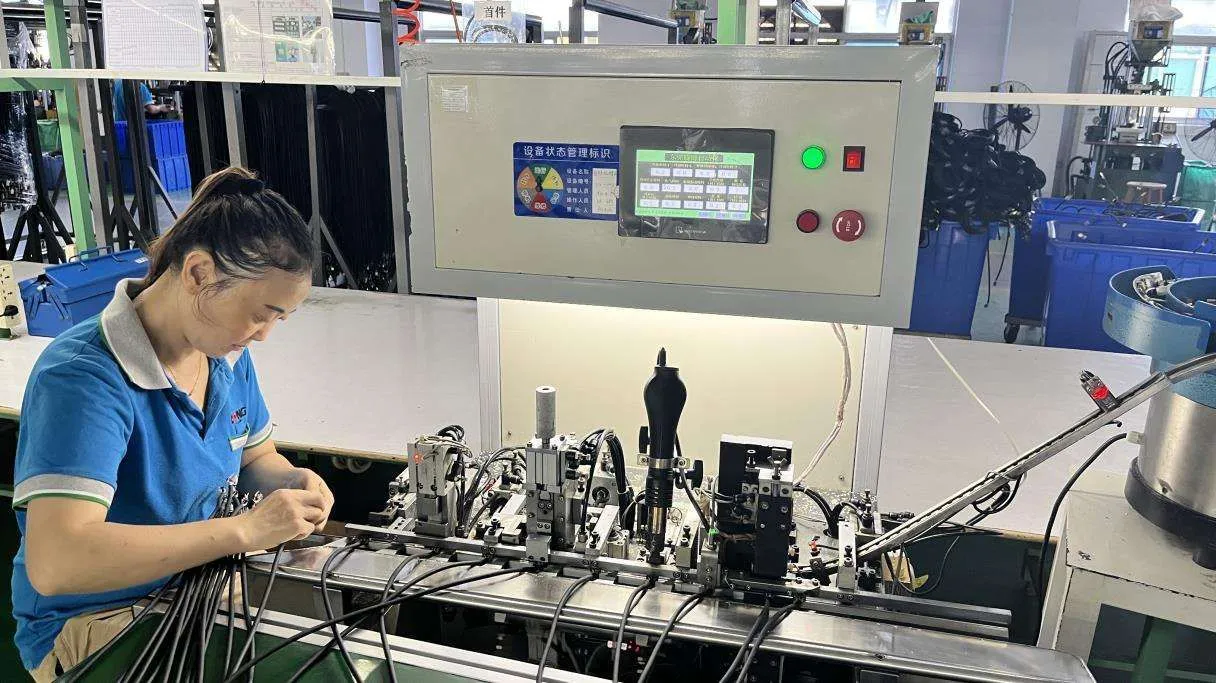

3. In-Process Manufacturing Control

Precision is monitored in real-time on the production floor.

Automated Monitoring: Using automated systems to maintain consistent tolerances during cabling, shielding, and jacketing.

Operator Checks: Line operators perform regular visual and electrical checks to catch any deviations immediately.

Process Documentation: Every batch is tracked for complete traceability.

4. Final Product Verification & Certification

This is where our promise is proven. Every finished cable must pass:

Electrical Performance Testing: Using tools like TDR (Time Domain Reflectometry) to verify signal integrity and pinpoint any internal faults in HDMI and DisplayPort cables.

Professional Compliance Certification: Employing Fluke Networks cable analyzers to certify that our Ethernet cables (including CAT8) meet all specified bandwidth, speed, and PoE performance standards.

Mechanical & Durability Testing: Testing plug connectors for insertion durability, cable flex life, and strain relief.

Safeguarding quality is a team effort

Producing quality cables is a team effort requiring the joint support of the line operators, cleaning and changeover crews, and manufacturing/packaging management. Our inspection technologies provide accurate data readings, and they are backed up by the sharp senses of our inspectors, allowing us to faithfully meet your specifications.

Your Assurance, Our Promise

This systematic approach allows us to prevent defects, ensure consistency, and deliver on our performance claims. When you choose ZONG Cable, you are choosing a product that has been meticulously engineered and validated to provide a seamless and trustworthy connection.

We build quality in, so you can plug confidence in.

Request a Free Quote

Explore our top-selling cables that meet your market’s needs. Fill out the contact form below or give us a call today.

Reply within 24 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

+86 13543026126

zongcarrie@zh-zong.com